6"-12" Ductile iron conforming to ASTM A 536, Grade 65-45-12

Clapper Facing: (Specify when ordering)

Grade E EPDM

-40�� to 230��F (-40�� to 110��C) Service Temperature Range Recommended for water service, dilute acids, alkaline, oil-free air and many chemical services.

NOT FOR USE IN PETROLEUM SERVICES.

Grade T Nitrile:

-20�� to 180��F (-29�� to 80��C) Service Temperature Range Recommended for petroleum products, air with oil vapors, vegetable oils and mineral oils.

NOT FOR USE IN HOT WATER SERVICES

Seat Ring: Type 304 stainless steel to ASTM A 123, ASTM A 213, ASTM A 312 or ASTM A 269

Flow Data: The approximate friction losses, based on the Hazen and Williams formula, expressed in equivalent length of pipe is given below. The friction losses have been calculated on the basis of flow rates typically used with each size valve.

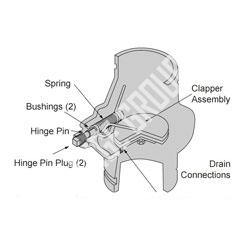

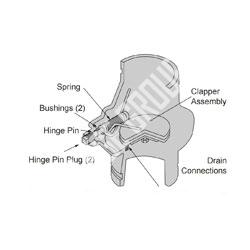

Spring: Type 302 stainless steel to ASTM A 313

Hinge Pin: Type 304 or 302 stainless steel to ASTM A 580

Hinge Pin Bushings: Sintered bronze to ASTM B 438

Hinge Pin Plugs and Drain Plugs: Cast iron to ASTM A 126 Class A

Material Specifications:

Body: Ductile iron conforming to ASTM A 536, Grade 65-45-12

Coating: Rust inhibiting paint on exterior - color, orange

Nickel Electroplated, Zn Electroplated (optional)

Clapper: 2"- 5" Type 304 or 302 stainless steel to ASTM A 167 |